Pilot Plant Development

CMYK Research offers a comprehensive pilot plant development service that can help you to bring your product or process to market quickly and successfully. Our team of experienced engineers and scientists will work with you to design, build, and operate a pilot plant that meets your specific needs. We will also provide you with the data and support you need to make informed decisions about your product or process.

What problems does a scientific feasibility study solve?

Identifying and resolving scale-up issues

When a product or process is scaled up from the lab to the commercial size, there are often unexpected challenges that can arise. Pilot plant development can help to identify and resolve these challenges before they become problems in the commercial plant.

Demonstrating commercial feasibility:

Pilot plant development can be used to demonstrate the commercial feasibility of a product or process. This can be important for securing funding or attracting customers.

Improving product quality

Pilot plant development can be used to improve the quality of a product or process. This can be done by optimizing the process conditions and by identifying and eliminating sources of variability.

Reducing production costs

Risks of Not Conducting A Feasibility Study

A feasibility study is a process that evaluates the practicality and viability of a proposed project. It considers all aspects of the project, including the technical, financial, and legal feasibility.

There are several risks associated with not conducting a feasibility study, including:

- The project may not be feasible.

- The project may not be successful.

- The project may cost more than expected.

- The project may take longer than expected.

The project may not be feasible.

A feasibility study can help to identify and mitigate risks before they become problems. For example, a feasibility study can help to identify technical challenges that may prevent the project from being completed

The project may not be successful.

A feasibility study can help to identify factors that may contribute to the project’s success or failure. For example, a feasibility study can help to identify the target market for the project and the competition.

The project may cost more than expected.

A feasibility study can help to identify the costs associated with the project, including the cost of materials, labor, and equipment. This information can help to ensure that the project is within budget

The project may take longer than expected

Benefits

Reduced Risk

Pilot plant development can help to reduce the risk of failure in the commercial plant. This is because the problems that can arise during scale-up can be identified and resolved in the pilot plant.

Increased speed to Market

Pilot plant development can help to increase the speed to market for a product or process. This is because the time and resources required to develop a product or process can be significantly reduced by using a pilot plant.

Improved Product Quality

Pilot plant development can help to improve the quality of a product or process. This is because the process conditions can be optimized and sources of variability can be identified and eliminated.

Reduced production Cost

If you are considering a scientific project, a feasibility study is a valuable tool that can help to increase your chances of success.

How Do We Conduct Pilot Plant

A pilot plant project is a complex and time-consuming process, but it is essential for ensuring the success of a new product or process. CMYK Research has the expertise and experience to help you with every step of the pilot plant project, from gathering the requirements to analyzing the data. Contact us today to learn more about our pilot plant services.

Step 1:

Gathering Client Requirements

The first step in a pilot plant project is to gather the requirements from the client. This includes information such as:

- The product or process to be scaled up

- The desired capacity

- The quality standards

- The budget

Once the requirements have been gathered, CMYK Research can begin to develop a plan for the project.

Step 2:

Conduct Lab Scale Research

If lab-scale research has not already been conducted, CMYK Research will need to conduct this research in order to gather data on the product or process. This research will help to determine the feasibility of scaling up the product or process, and it will also provide information on the equipment and process conditions that will be needed.

Step 3:

Design Pilot Plant

Once the lab-scale research has been completed, CMYK Research can begin to design the pilot plant. This involves selecting the appropriate equipment, determining the process conditions, and developing a plan for the construction and operation of the pilot plant.

Step 4:

Construction The Pilot Plant

The next step is to construct the pilot plant. This involves assembling the equipment and installing it in a suitable facility. CMYK Research has a state-of-the-art facility that is equipped with the latest equipment, and we have a team of experienced engineers and scientists who can oversee the construction of the pilot plant.

Step 5:

Operate The Pilot Plant

Once the pilot plant has been constructed, it is time to begin operating it. This involves running the process and collecting data. CMYK Research has a team of experienced engineers and scientists who can operate the pilot plant and collect the data that is needed.

Step 6:

Analyze The Data

The final step in a pilot plant project is to analyze the data that was collected during the operation of the pilot plant. This data will be used to identify any scale-up issues and to make recommendations for improving the product or process. CMYK Research has a team of experienced engineers and scientists who can analyze the data and make recommendations.

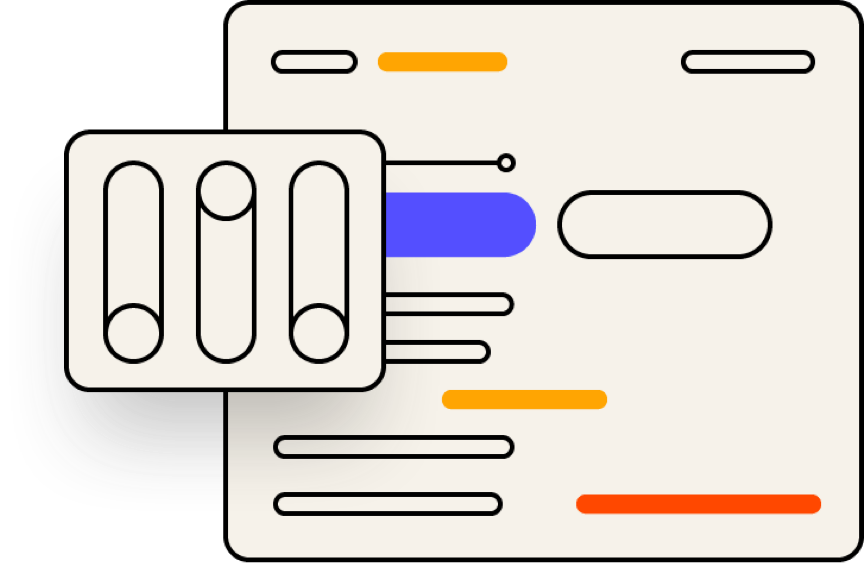

Pricing Plans

A Plan For Every Business Size

Our pricing model is based on project complexity, safety & legal requirements. Here it must be noted that every project is first evaluated for its feasibility

Evaluationa Criteria

Project Evaluation

Once a project is received it is evaluated on certain factors to ensure complaince with local & international regulatory requirements. Once this evaluation stage is cleared, then the project execution phase is started

Basic

$5000-8000 / Project

- Lab-scale research

- Pilot plant design

- Pilot plant construction

- Pilot plant operation

- Data analysis

- Pilot plant commissioning

Ideal For

* Small-scale projects

* Projects with a limited budget

* Ideal for startups and small businesses

PRO

$8000-$12000 / Project

Everything in Package 1

- Additional services, such as:

- Process optimization

- Scale-up studies

- Regulatory support

- Pilot plant commissioning

Ideal For:

* Medium-scale projects

* Projects with a moderate budget

* Ideal for established companies that are looking to scale up their operations

Enterprise

$12000-$25000 / Project

Everything in Package 2

- Additional services, such as:

- Custom equipment design

- Process training

- Pilot plant startup and commissioning

Idea For

* Large-scale projects

* Projects with a high budget

* Ideal for multinational corporations that are looking to develop new products or processes

Frequently Asked Questions

What is Pilot Plant Development?

Pilot Plant Development is the process of taking a product or process that has been developed in the lab and scaling it up to a commercial size. This process can be complex and time-consuming, but it is essential to ensure that the product or process can be manufactured efficiently and cost-effectively.

What is the relationship between Pilot Plant Development and Lab-scale Research?

Lab-scale research is the process of developing a new product or process in a laboratory setting. This process is typically less expensive and less time-consuming than Pilot Plant Development, but it is also less representative of the conditions that will be encountered in a commercial plant. Pilot Plant Development is typically conducted after Lab-scale Research has been completed, and it is used to confirm the results of the Lab-scale research and to identify any scale-up issues.

What are the benefits of using a Pilot Plant?

There are many benefits to using a Pilot Plant, including:

Reduced risk:Pilot Plant Development can help to reduce the risk of failure in the commercial plant. This is because the problems that can arise during scale-up can be identified and resolved in the pilot plant.

Increased speed to market:Pilot Plant Development can help to increase the speed to market for a product or process. This is because the time and resources required to develop a product or process can be significantly reduced by using a pilot plant.

Improved product quality: Pilot Plant Development can help to improve the quality of a product or process. This is because the process conditions can be optimized and sources of variability can be identified and eliminated.

Reduced production costs:

Pilot Plant Development can help to reduce the production costs of a product or process. This is because more efficient and cost-effective manufacturing methods can be identified and implemented.

What are the steps involved in Pilot Plant Development?

The steps involved in Pilot Plant Development vary depending on the specific product or process being developed. However, some common steps include:

Design:

The first step is to design the pilot plant. This involves selecting the appropriate equipment and determining the process conditions.

Construction:

The next step is to construct the pilot plant. This involves assembling the equipment and installing it in a suitable facility.

Operation:

The next step is to operate the pilot plant. This involves running the process and collecting data.

Analysis: The final step is to analyze the data and make recommendations. This involves identifying any scale-up issues and making recommendations for improving the product or process.

What are the costs of Pilot Plant Development?

The costs of Pilot Plant Development vary depending on the size and complexity of the project. However, the costs typically include the cost of equipment, facility, labor, and materials.

What is the timeline for Pilot Plant Development?

The timeline for Pilot Plant Development varies depending on the size and complexity of the project. However, a Pilot Plant Development project typically takes several months to complete.

What are the risks associated with Pilot Plant Development?

There are some risks associated with Pilot Plant Development, including:

The project may not be successful: There is always a risk that a Pilot Plant Development project may not be successful. This could be due to a number of factors, such as technical challenges, cost overruns, or delays.

The project may not be completed on time: There is also a risk that a Pilot Plant Development project may not be completed on time. This could be due to a number of factors, such as unexpected delays or changes in scope.

The project may exceed budget: There is also a risk that a Pilot Plant Development project may exceed budget. This could be due to a number of factors, such as unexpected cost increases or changes in scope.

What are the benefits of using CMYK Research for Pilot Plant Development?

CMYK Research is a leading provider of Pilot Plant Development services. We have a team of experienced engineers and scientists who can help you to develop your product or process from lab-scale to commercial scale. We also have a state-of-the-art facility that is equipped with the latest equipment.

How can I get started with Pilot Plant Development at CMYK Research?

To get started with Pilot Plant Development at CMYK Research, please contact us to discuss your project. We will be happy to answer your questions and provide you with a quote.

What are the next steps for me?

The next steps for you will depend on your specific situation. However, some possible next steps include:

* Contact CMYK Research to discuss your project.

* Review our website for more information

Paint Manufacturing CompanyCase Study

A paint manufacturing company was developing a new line of environmentally friendly paints. The paints were based on a new waterborne resin system, and the company was concerned about the potential for the paints to be too thin and runny. The company hired a team of engineers and scientists to design and build a pilot plant. The pilot plant was used to test the paints at a larger scale and to identify any potential problems. The pilot plant also allowed the company to optimize the process and to improve the viscosity of the paints. As a result of the pilot plant, the company was able to successfully develop the new line of paints and bring them to market.

**Key Takeaways:**

* Pilot plant development is an essential step in the development of new products, especially those that are based on new technologies.

* Pilot plants can help to identify and mitigate potential problems with the product or process before it is scaled up to commercial size.

* Pilot plants can help to ensure that the product meets the desired quality standards.

* Pilot plants can help the company to comply with all applicable regulations.

Printing Ink Manufacturing CompanyCase Study

A printing inks manufacturing company was developing a new line of high-performance inks for use in high-speed printing applications. The inks were based on a new resin system, and the company was concerned about the potential for the inks to be too viscous and to clog the print heads. The company hired a team of engineers and scientists to design and build a pilot plant. The pilot plant was used to test the inks at a larger scale and to identify any potential problems. The pilot plant also allowed the company to optimize the process and to improve the flow properties of the inks. As a result of the pilot plant, the company was able to successfully develop the new line of inks and bring them to market.

**Key Takeaways:**

* Pilot plant development is an essential step in the development of new products, especially those that are based on new technologies.

* Pilot plants can help to identify and mitigate potential problems with the product or process before it is scaled up to commercial size.

* Pilot plants can help to ensure that the product meets the desired quality standards.

* Pilot plants can help the company to comply with all applicable regulations.

In addition to the key takeaways above, here are some other benefits of pilot plant development:

* Pilot plant development can help to reduce the risk of failure. By testing the product or process at a larger scale, companies can identify and mitigate potential problems before they occur. This can save companies time and money in the long run.

* Pilot plant development can help to improve the efficiency of the process. By optimizing the process at a smaller scale, companies can identify ways to improve the efficiency of the process when it is scaled up to commercial size. This can lead to lower costs and increased profits.

* Pilot plant development can help to improve the quality of the product. By testing the product at a larger scale, companies can identify ways to improve the quality of the product. This can lead to increased customer satisfaction and repeat business.

Overall, pilot plant development is an essential step in the development of new products and processes. It can help to ensure that the product or process is successful and that it meets the needs of the company and its customers.